Your project large or small is in expert hands. GSS will guide you through every aspect of your project from inception through to design and installation.

Working in close partnership with selected heat pump manufacturers we are able to offer a complete service package to our clients. We can guide you through every step. All of our work is carried out by experienced, highly trained staff and in accordance with the GSHPA and IGSHPA standards.

Ground Source System Design

We have our own in-house design team that consists of certified and accredited Geo-exchange Designers and Cad Technicians enabling us to design a highly efficient and compliant ground source system using the latest industry software.

With the information provided from your building parameters and the ground, we are able to perform a simulation of the ground loop heat exchanger and determine the required depth and number of boreholes required to provide an efficiently performing system. If required we can carry out a Thermal Response Test (TRT) of the borehole. This will enable us to determine the performance of the Ground Loop.

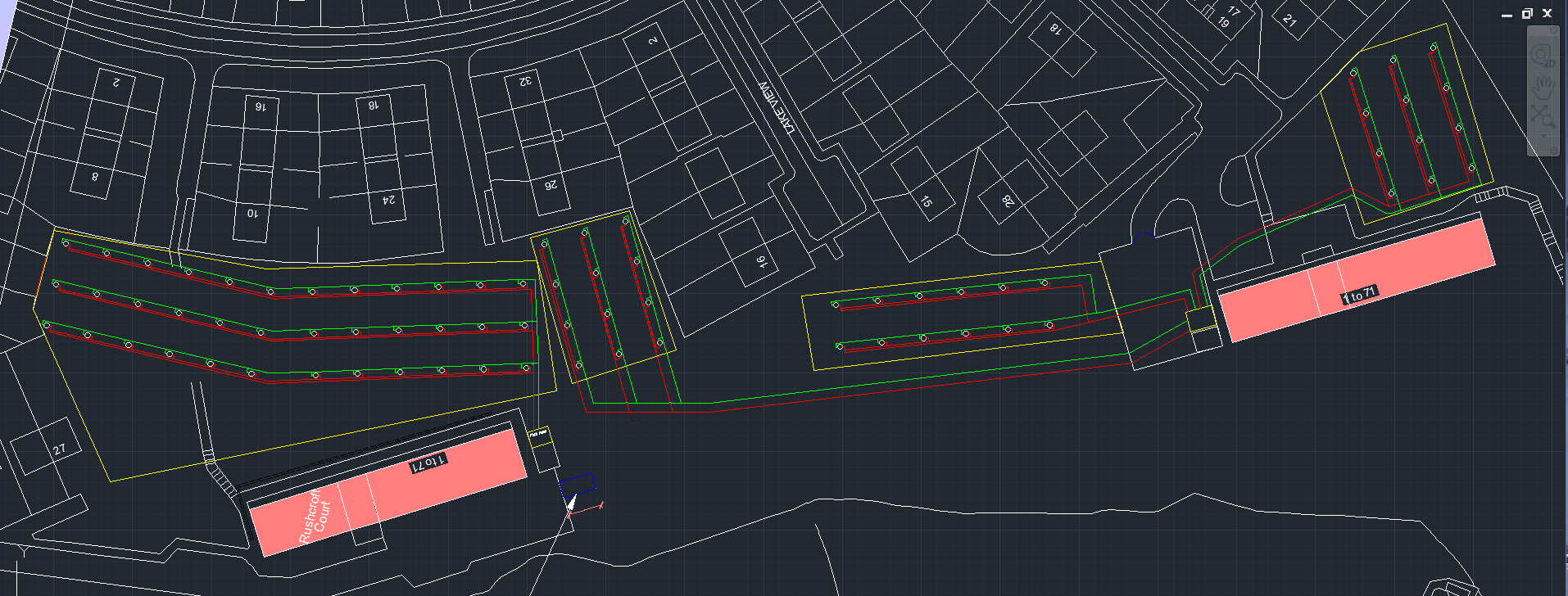

Using the latest CAD software and other technologies our in-house technician will create a professional drawing package that clearly communicates your project design and keeps an accurate record of your installation and precise locations. All of our drawings meet industry standards and are legally compliant.

- Borehole schematics

- Site Plans

- Pipework layouts

- Plant room schematics

- Borehole mapping

- Drone surveillance

Ground Loop Installation

Our installation team are equipped with specialised training and equipment to deliver a quality and efficient install.

NVQ Level 2 trained Drillers, Site Supervisors, CPCS Plant Operators, Fusion Pipe Installers and qualified First Aiders all operating within strict Health & Safety guidelines.

Our modern drilling rigs are designed specifically to carry out our works. Rubber crawler tracks ensure minimum disruption to the working area and drill rod handling systems eliminate manual handling for our crew.

By comparing the above image of a ground loop installation and the adjacent image, it’s possible to see how we “make good” of the site area after an installation is completed.

GSS has a drilling capability of up to 300m depth and 500mm diameter.

We use high quality, environmentally friendly materials for longevity and performance and our pipework carries a manufacturer’s guarantee.

The ground loops are flow and pressure tested before installation into the borehole. The borehole is then backfilled with a thermally enhanced grout which prevents cross contamination and ensures optimum heat transfer. A final flow and pressure test is performed to provide a fully commissioned system.

GNSS

Ground Source Solutions uses GNSS (global navigation satellite system) to plot the boreholes drilled on site within 20mm accuracy providing the client with easting and northing positions using the national grid 1936 coordinate system. This allows us to quickly locate the boreholes if anything were to happen to the loops after completion. This saves time finding the faulty loop after it all gets covered up. And also saves the area from becoming a mess trying to find the loop.

We use GNSS in conjunction with CAD software to plot boreholes on the map and provide the client with an accurate drawing to avoid the loops during further development.